Dr. Dan Luss

Cullen Professor EmeritusMember, National Academy of Engineering

- CHEE 3369: Chemical Engineering Transport Processes

- CHEE 4367: Chemical Reaction Engineering

- CHEE 6337: Advanced Chemical Reaction Engineering

Dr. Luss's group is currently conducting research on several topics. The main emphasis is on problem related to the reduction of environmental emissions from diesel engines. These include enhancement of the efficiency and safety of the regeneration diesel particulate filters, development of novel catalyst architectures which improve the destruction of NOx and organic compounds emitted by diesel engines. We also conduct studies of novel synthesis of solid oxides and the dynamic features of the combustion of solid nano-particles. Specific research projects include:

Combustion of soot in diesel particulate filters

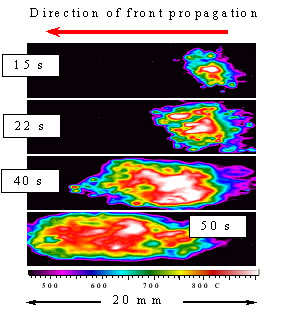

Particulate solid particles (soot) emitted by diesel engines are a serious health hazard as they can cause cancer. The best technology for its removal is by use of special ceramic and periodic combustion of the accumulated particulate matter. Experience has indicated the transient change in the load of the engine leads sometimes to excessive unexpected temperature excursions that can melt and /or crack the expensive catalyst. We are conducting both experimental and simulation studies that aim to determine the operating conditions and driving modes that can lead to these excessive temperature rise in order to enable development of control protocols that will circumvent these undesirable dynamic behavior.

Development of temperature waves during soot combustion in a Diesel Particulate Fiter (DPF)

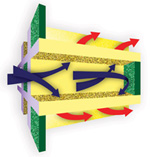

Flow pattern in a DPF

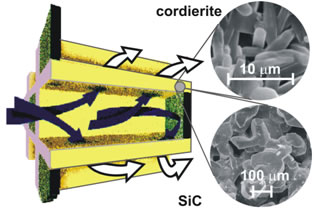

Development of novel catalyst Architecture

A major research activity in the department is the reduction of NOx emissions in the oxidizing exhaust emissions of diesel engines. This reduction may be conducted by use of selective Catalytic reduction catalyst (SCR) which required feed of ammonia precursor or by use of Lean NOx Trap (LNT) which contains expensive precious metals. Another option is the use a reactor with LNT catalyst followed by one with SCR to avoid the need to inject ammonia precursors. We are conducting both experimental and simulation studies of novel catalyst architecture with goal to enable a reduction of the expensive precious metal without affecting the effectiveness of the NOx destruction.

Novel temperature measurements of temperature in honeycomb reactors.

The presence of excessive high local temperatures (hot spots) can severely damage chemical reactors and monolith reactors used to destruct environmental pollutants. There is a technological to detect the amplitude and motion of small hot zones the location of which is not known and which may meander with time. We have recently developed a novel technique for measuring the spatio-temporal temperature, which measures a continuously the temporal temperature profile along a special optical fiber. The technique is currently used to measure the temperature profiles in a monolith reactor and a packed bed reactor in which several reactions are conducted. This novel technique is expected to lead to major advances in the measurements and control of temperature in chemical reactors and provide essential information that could not have been obtained until now.

Nano-particles synthesis and pressure release during their combustion

We have developed a novel method for the synthesis of solid oxides by having a high temperature front propagate through a mixture of carbon and some minerals. The method (which has a 2mm spatial resolution and temperature resolution of 0.5 C) enables a more economic synthesis than do other methods. Moreover, it can be used directly to produce nano-particles. We conduct studies on the impact of the operating conditions and reactants mixture composition on the product properties and the magnitude of the amplitude and duration of the pressure pulse generated by the released gaseous products and its dependence on the nano particles size.

1969: Honor Scroll award of IEC Division of ACS

1972: Allan P. Colburn Award of the AIChE

1977: Curtis W. McGraw Research Award of the ASEE

1979: Professional Progress Award of the AIChE

1984: Elected to National Academy of Engineering

1985: ASEE Chemical Engineering Division Lectureship Award

1986: Wilhelm Award of the AIChE

1990: Fellow of the AIChE

1996: Research Award by the Alexander von Humboldt Foundation, Germany

2004: Sartorius India’s Chemcon Distinguished Speaker Award

2005: Founders Award of the AIChE

2010: Amundson Award, ISCRE

Board of Consulting Editors, McGraw-Hill Encyclopedia of Science & Technology, 2005-present.

Editor, Reviews in Chemical Engineering, 1982-present

Editor, Plenum, Chemical Engineering Series, 1983-2009

Editorial Board. Industrial Engineering Chemical Research, 2005-2008

Associate Editor, Catalysis Reviews, Science and Engineering, November 1973-2008

Editorial Board, Chemical Engineering Fundamentals, 1982-1983

Editorial Board, AIChE Journal, November 1973-1980

Selected Publications

- Dadi, R. K., Luss, D., & Balakotaiah, V., "Dynamic hysteresis in monolith reactors and hysteresis effects during co-oxidation of CO and C2H6", Chemical Engineering Journal, 297, 325-340, DOI: 10.1016/j.cej.2016.03.139, 2016

- Dadi, R. K., Luss, D., & Balakotaiah, V., "Bifurcation features of mixtures containing CO and hydrocarbons in diesel oxidation catalyst", Chemical Engineering Journal, 304, 941-952, DOI: 10.1016/j.cej.2016.06.119, 2016

- Zheng, Y., Harold, M. P., & Luss, D., "Effects of CO, H-2 and C3H6 on Cu-SSZ-13 catalyzed NH3-SCR", Catalysis Today, 264, 44-54, DOI: 10.1016/j.cattod2015.06.028, 2016

- Zheng, Y., Li, M. M., Wang, D., Harold, M. P., & Luss, D., "Rapid propylene pulsing for enhanced low temperature NOx conversion on combined LNT-SCR catalysts", Catalysis Today, 267, 192-201, DOI: 10.1016/j.cattod.2015.10.029, 2016

- Y. Zheng, , D. Luss, and M.P. Harold, "Optimization of LNT-SCR Dual-Layer Catalysts for Diesel NOx Emission Control,"SAE Int. J. Engines 7, 1280-1289, 2014

- Zheng, Y., Liu, Y., Harold, M. P., & Luss, D., LNT-SCR dual-layer catalysts optimized for lean NOx reduction by H-2 and CO. Applied Catalysis B-Environmental, 148, 311-321, 2014

- A.S. Kota, D. Luss, V. Balakotaiah, “Modeling Studies on Low Temperature Aerobic NOx Reduction by a Sequence of LNT-SCR Bricks”’ AIChE J, 3421-3431, 2013

- G. Kolios, Dan Luss, R.Garg, G. Viswanathan, “Efficient computations of periodic state of cyclic fixed bed processes”, Chem. Eng. Sci., 101,90-98, 2013

- Hoang Nguyen, Michael P. Harold, Dan Luss, "Optical frequency domain reflectometry measurements of spatio-temporal temperature inside catalytic reactors: Applied to study wrong-way behavior", Chem. Eng. J., 234, 312-317, 2013

- M. Yu, D. Luss and V. Balakotaiah, “Regeneration modes and peak temperatures in a diesel particulate filter", Chem. Eng. J, 232, 541-554, 2013

- M. Yu, D. Luss, V. Balakotaiah, “Analysis of Ignition in a Diesel Particulate Filter”, Cat Today, 216, 158-168, 2013

- Mengting Yu, Dan Luss, V. Balakotaiah, “Regeneration modes and peak temperatures in a diesel particulate filter”, Chem. Eng. J, 232, 541-554, 2013

- Y. Liu, Y. Zheng, M.P. Harold and D. Luss, “Lean NOx reduction on LNT-SCR dual-layer catalysts by H2 and CO”, Appl. Cat. B. 132-133, 293-303, 2013

- Y. Liu, Y. Zheng, M.P. Harold and D. Luss, “Lean NOx reduction with H2 and CO in Dual Layer LNT-SCR Monolithic Catalysts: Impact of Ceria Loading", Topics Catal., 56, 104-108, 2013

- Yu, M.T., Luss, D. & Balakotaiah, V., "Analysis of flow distribution and heat transfer in a diesel particulate filter", Chemical Engineering Journal 226, 68-78, 2013

- Kota, A.S., Luss, D. & Balakotaiah, V., "Modeling Studies on Lean NOx Reduction by a Sequence of LNT-SCR Bricks", Industrial & Engineering Chemistry Research 51, 6686-6696, 2012

- Liu, Y., Harold, M.P. & Luss, D., "Coupled NOx storage and reduction and selective catalytic reduction using dual-layer monolithic catalysts", Applied Catalysis B-Environmental 121, 239-251, 2012

- Yu, M.T. & Luss, D., "Inlet Cone Effect on Particulate Matter Deposition and Regeneration Temperature in a Diesel Particulate Filter", Industrial & Engineering Chemistry Research51, 3791-3800, 2012

- Yu, M.T. & Luss, D., "Inlet Cone Effect on Diesel Particulate Filter Regeneration upon a Rapid Shift to Idle", Industrial & Engineering Chemistry Research 51, 11355-11366, 2012

- A. Varma and D. Luss, “Neal Amundson - ChE Educator, Researcher and Leader Par Excellence,” CEP, 107, 4, 51-55, 2011

- Chen, K.; Luss, D., Temperature Excursions in Diesel Particulate Filters: Response to Shift to Idle. Industrial & Engineering Chemistry Research 2011, 50 (2), 832-842., 2011

- Chen, K.; Martirosyan, K. S.; Luss, D., Counter-Intuitive Temperature Excursions During Regeneration of a Diesel Particulate Filter. Aiche Journal 2011, 57 (8), 2229-2236., 2011

- Chen, K.; Martirosyan, K. S.; Luss, D., Transient temperature rise during regeneration of diesel particulate filters. Chemical Engineering Journal 2011, 176-77, 144-150., 2011

- Chen, K.; Martirosyan, K. S.; Luss, D., Hot Zones Formation During Regeneration of Diesel Particulate Filters. Aiche Journal 2011, 57 (2), 497-506., 2011

- Chen, K.; Martirosyan, K. S.; Luss, D., Temperature gradients within a soot layer during DPF regeneration. Chemical Engineering Science 2011, 66 (13), 2968-2973., 2011

- K. Chen and D. Luss, “Temperature excursions in diesel particulate filters: Response to shift to idle,” Ind. Eng. Chem. Res., 50, 832-842, 2011

- K. Chen and D. Luss, “Temperature rise during stationary and dynamic regeneration of a diesel particulate filter,” Rev. Chem. Eng., 27,133-147, 2011

- K. Chen, K.S. Martirosyan and D. Luss, “Temperature gradients within a soot layer during DPF regeneration,” Chem. Eng. Sci., 66, 2968-2973, 2011

- K. Chen, K.S. Martirosyan and D. Luss, “Transient temperature rise during regeneration of diesel particulate filters,” Chem. Eng. J., to be published, 2011

- K. Chen, K.S. Martirosyan and D. Luss, “Hot zones formation during regeneration of Diesel Particulate Filters,” AIChEJ, 57, 497-506, 2011

- K. Chen, K.S. Martirosyan and D. Luss, “Counter-intuitive temperature excursions during regeneration of a Diesel Particulate Filter,” accepted for publication, AIChEJ., 57, 2231-2236, 2011

- K.S. Martirosyan, L Wang, and D. Luss, “Tuning the gas pressure discharge of nano-energetic materials by boron and carbon nano-tubes additives,” NSTI-Nanotech, 1, 323-326, 2011

- L Wang, K.S. Martirosyan, and D. Luss, “The behavior of nanothermite reaction based on Bi2O3/Al,” J. Appl. Phys., 110, 74311 1-7, 2011

- Liu, Y.; Harold, M. P.; Luss, D., Spatio-temporal features of periodic oxidation of H(2) and CO on Pt/CeO(2)/Al(2)O(3). Applied Catalysis a-General 2011, 397 (1-2), 35-45., 2011

- Wang, L.; Luss, D.; Martirosyan, K. S., The behavior of nanothermite reaction based on Bi(2)O(3)/Al. Journal of Applied Physics 2011, 110 (7)., 2011

- Y. Liu, M.P. Harold and D. Luss, “Spatio-temporal features of periodic oxidation of H2 and CO on Pt/.CeO2/Al2O3,” Appl. Cat., 397, 35-45, 2011

- K. S. Martirosyan, Luss, D., “Temperature Excursions during Soot Combustion in a Diesel Particulate Filter (DPF)2231,” Ind. Eng. Chem. Res., 49 (21), 10358-10363, 2010

- K.S. Martirosyan, K. Chen and D. Luss, “Behavior Features of Soot Combustion in Diesel Particulate Filter,” Chem. Eng. Sci., 65, 42-46, 2010

- K.S. Martirosyan, L Wang, and D. Luss, “Development of nano-energetic materials based on Al/I2O5 system,” Nanotechnology, 2, 137-140, 2010

Selected Publications

- K. Chen, K.S. Martirosyan and D. Luss, “Soot combustion dynamics in a planar diesel particulate filter,” Ind. Eng. Chem. Res., 48, 3323-3330, 2009

- K. Chen, K.S. Martirosyan and D. Luss, “Wrong-way behavior of soot combustion in a planar diesel particulate filter,” Ind. Eng. Chem. Res., 48, 8451-8456, 2009

- K.S. Martirosyan and D. Luss, “Fabrication of metal oxides Nanoparticles by highly exothermic reactions,” Chem. Eng. Techn., 32, 9, 1376-1383, 2009

- K.S. Martirosyan, L Wang, A. and D. Luss, “Novel nanoenergetic system based on iodine pentoxide,” Chem. Phys. Lett., 483, 107-110, 2009

- K.S. Martirosyan, L Wang, A. Vicent, and D. Luss, “Fabrication of Bismuth Trioxide Nanoparticles for gas Generators Applications,” NSTI-Nanotechnology,20, 82-85, 2009

- K.S. Martirosyan, L Wang, A. Vicent, and D. Luss, “Fabrication of Bismuth Trioxide Nanoparticles for gas Generators Applications,” NSTI-NANO Tech., 1, 82-85, 2009

- K.S. Martirosyan, L Wang, A. Vicent, and D. Luss, “Fabrication of Metal Oxides Nanoparticles by Highly Exothermic Reactions,” Chem. Eng. & Tech., 32, No. 9, 1, 2009

- K.S. Martirosyan, L Wang, A. Vicent, and D. Luss, “Nanoenergetic Gas-Generator: Design and Performance,” Propellants, Explosives, Pyrotechnics, to be published, 2009

- G. Viswanathan, M. Sheintuch, and D. Luss, “Transversal Hot Zones Formation in Catalytic Packed-Bed Reactors,” I&EC Res, 47, 2509-2523, 2008

- K.S. Martirosyan, E. Galstyan, Y.Y. Xue, and D. Luss, “The fabrication of YBCO Superconductor Polycrystalline Powder by CCSO,” Superconductor Science and Technology, 21, 065008, 2008

- P. Hamilton, and D. Luss, “Catalyst particle design for optimum polyolefin productivity,”IEC Res., 47, 2905-2911, 2008

- P. Hamilton, D. Hill and D. Luss, “Optical and Infrared Study of Individual Reacting Metallocene Catalyst Particles,” AIChE J., 54, 1054-1063, 2008

- B. Pinkerton and D. Luss, “Hot zone formation during hydrogenation of ethylene and acetylene mixtures in a shallow packed bed reactor,” I&EC Res, 46, 1898, 2007

- K. Gerdes and D. Luss, “Oxygen flux increases through MIEC membranes by enhanced surface exchange,” AIChE J., 53, 1389, 2007

- K. S. Martirosyan and D. Luss, “Carbon combustion synthesis of ferrites: Synthesis and characterization,” IEC Res., 46, 1492, 2007

- K. S. Martirosyan, D. Litvinov and D. Luss, “Novel synthesis method of micro- and nanostructures complex oxides,” in “Combustion of heterogeneous systems: Fundamentals and applications for materials synthesis,” A.S. Mukasyan and K. S. Martirosyan, eds., Transworld Research Network, 67-101, 2007

- K. S. Martirosyan, M. Iliev and D. Luss, “Carbon combustion synthesis of nanostructures perovskites,” Int. J. SHS, 16, 36-45, 2007

- K.S. Martirosyan, L. Chang, J. Rantschler, S. Khizroev, D. Luss, and D. Litvinov, “Carbon Combustion Synthesis and Magnetic Properties of Cobalt Ferrite Nanoparticles,” IEEE Transactions on Magnetics, 43, 6, 3118-3120, 2007

- P. Hamilton, Hao Song and D. Luss, “Dual-site supported metallocene catalyst design for bimodal polyolefin synthesis,” AIChE J., 53, 687, 2007

- S. Sundarram, and D. Luss, “Transversal hot zones in a shallow packed bed reactor during oxidation of mixtures of C3H6 and CO,” I&EC Res, 46, 1485, 2007

- S. Sundarram, G. Viswanathan and D. Luss, “Reactor diameter impact on hot zone dynamics in an adiabatic packed bed reactor,” AIChE J., 53, 1578, 2007

- D. Luss, “Challenging reaction Engineering problems,” in Studies in Surface Science and Catalysis, 159, 1, 2006

- G. Viswanathan and D. Luss, “Moving transversal hot zones in adiabatic, shallow packed bed reactors,” AIChE J., 52, 705, 2006

- G. Viswanathan and D. Luss, “Model prediction of hot spot formation in shallow adiabatic packed bed reactors,” AIChE J., 52, 1533, 2006

- G. Viswanathan and D. Luss, “Hot zones formation and dynamics in long adiabatic packed-bed reactors,” I&EC Res., 45, 7057, 2006

- K. Gerdes and D. Luss, “Directional dependence of oxygen ionic transport in a tubular MIEC membrane,” Solid State Ionics, 177, 1157, 2006

- K. Gerdes and D. Luss, “Oxygen transport model for layered MIEC composite membranes,” Solid State Ionics, 177, 2931, 2006

- K. S. Martirosyan, D. Nawarathna, J. R. Claycomb, J. H. Miller, Jr and D. Luss, “Complex dielectric behavior during formation of BaTiO3 by combustion synthesis,” J. of Phys. D: Appl. Phys., 39, 3689, 2006

- K. S. Martirosyan, M. Setoodeh, D. Luss, “Electric pulse formation during high temperature reaction between Ni and Al,” J. Appl. Phys., 99, 84901, 2006

- A. Filimonov and D. Luss, “High-temperature oxidation of a metal particle: Nonisothermal model,” AIChE J., 51, 1521, 2005

- D. Luss and M. Sheintuch, “Spatiotemporal Patterns in Catalytic Systems,” Cat. Today, 105, 254, 2005

- G. Viswanathan, A. Bindal, J. Khinast and D. Luss, “Stationary transversal hot zones in adiabatic packed bed reactors,” AIChE J., 51, 3028, 2005

- K. S. Martirosyan, D. Luss, “Carbon Combustion Synthesis of Complex Oxides: Process demonstration and Features,” AIChE J., 51, 2801, 2005

- K. S. Martirosyan, M. Setoodeh, D. Luss, “Electric Field Generated by the Combustion of Titanium in Nitrogen,” J. Appl. Phys., 98, 54901, 2005

- S. Sundarram, B. Marwaha, D. Luss, “Global-coupling induced temperature patterns on top of packed-bed reactors,” Chem. Eng. Sci., 60, 6803, 2005

- B. Marwaha, S. Sundarram, and D. Luss, “Dynamics of Transversal Hot Zones in Shallow Packed-Bed Reactors,” J. Phys. Chem., 108, 2004

- B. Marwaha, S. Sundarram, D. Luss, “Dynamics of hot spots on top of packed-bed reactors,” Chem. Eng. Sci., 59, 5569, 2004

- H. Song and D. Luss, “Bounds on Operating Conditions Leading to Melting during Olefin Polymerization,” Ind. Eng. Chem. Res., 43, 270, 2004

- H. Song and D. Luss, “Impact of Initiation and Deactivation on Melting during Gas-Phase Olefin Polymerization,” Ind. Eng. Chem. Res., 43, 4789, 2004

- I. A. Filimonov and D. Luss, “Formation of Electrical Potential During the Oxidation of a Metal Particle,” AIChE J., 50, 2287, 2004

- K. S. Martirosyan, J. R. Claycomb, J. H. Miller, Jr and D. Luss, “Generation of the Transient Electrical and Spontaneous Magnetic Fields by Solid State Combustion,” J. Appl. Phys., 96, 4632, 2004

- K.S. Martirosyan, I. A. Filimonov, and D. Luss, “Electric Field Generation by Gas-Solid ombustion,” AIChE J., 50, 241, 2004

- B. Marwaha, and D. Luss, “Hot zones formation in packed bed reactors,” Chem. Eng. Sci., 58, 733, 2003

- K. S. Martirosyan, J. R. Claycomb, G. Gogoshin, R. A. Yarbrough J. H. Miller, Jr and D.Luss, “Spontaneous Magnetization Generated by Spin, Pulsating and Planar Combustion Synthesis,” J. Appl. Phys., 93, 9329, 2003

- K.S. Martirosyan, I. A. Filimonov, and D. Luss, “Self Heating by Joule dissipation during gas-solid combustion reactions,” Int. J. Self-Prop. High-Temp. Synthesis, 12, 91, 2003

- K.S. Martirosyan, I. A. Filimonov, M.D.Nersesyan, and D. Luss, “Electric Field Formationduring Combustion of Single Metal particles,” J. Electro. Chem. Soc., 150, J9, 2003

- Yong Ok Jeong and D. Luss, “Pollutant destruction in a reverse-flow chromatographic reactor,” Chem. Eng. Sci., 58, 1095, 2003

- B. Marwaha and D. Luss, “Formation and Dynamics of a Hot Zone in a Radial-Flow Reactor,” AIChE J., 48, 617, 2002

- D. Luss and B. Marwaha, “Hot-Zone Evolution and Dynamics in Heterogeneous Catalytic Systems,” Chaos, 12, 172, 2002

- K.S. Martirosyan, I. A. Filimonov, and D. Luss, “New Measuring Techniques of Electric Field Generated by Combustion Synthesis,” Int. J. Self-Prop. High-Temp. Synthesis, 11, 325, 2002

- M.D. Nersesyan, J.T. Ritchie, I.A. Filimonov, J.T. Richardson and D. Luss, “Electric Fields Produced by High-Temperature Metal Oxidation,” J. Electrochem. Soc., 149, J11, 2002

- R. Garg, A. Garayhi and D. Luss, “Influence of Product Adsorption on the Operation of a Reverse-Flow Reactor,” AIChE J., 48, 324, 2002

- V.I. Yukhvid, V.N. Sanin, M.D. Nersesyan and D. Luss, “Self-Propagating High temperature Synthesis of Oxide and Composite Materials under Centrifugal Forces,” Int. J. SHS, 11, 65, 2002

- D. Luss, “Novel Reactor Configurations and Modes of Operation,” pp. 71-85 in “Reaction Kinetics and the Development of Catalytic Processes,” G.F. Froment and K.C. Waugh eds., Vol 133,in Studies in Surface Science and Catalysis, Elsevier, NY, 2001

- Garg, R. and D. Luss, “Dynamic Bifurcations and Features of a Cooled Countercurrent Flow Reactor,” Chem. Eng. Sci., 56, 3719, 2001

- J. T. Ritchie, J.T. Richardson and D. Luss, “Ceramic Membrane Reactor for Synthesis Gas Production,” AIChE J., 47, 2092, 2001

- J.R. Claycomb, K.E. Bassler, J.H. Miller, Jr, M.D. Nersesyan and D. Luss, “Avalanche Behavior in the Dynamics of Chemical Bifurcations,” Phys. Rev. Lett., 87, 178303, 2001

- M.D. Nersesyan, J.R. Claycomb, J.T. Ritchie, J.H. Miller Jr. and D. Luss, “Magnetic Fields Produced by Combustion of Metals in Oxygen,” Combust. Sci. Tech., 169, 89, 2001

- M.D.Nersesyan, J.R. Claycomb, J.T. Ritchie, J.H. Miller, Jr., J.T. Richardson and D. Luss, “Electric and magnetic Fields generated by SHS,” J. Mater. Synth. and Proc., 9, 63, 2001

- Marwaha, Annamalai, J. and D. Luss, “Hot Zone Formation During Carbon Monoxide Oxidation in a Radial Flow Reactor,” Chem. Eng. Sci., 56, 89, 2001

- R. Garg, and D. Luss, “Dynamic bifurcations and features of a Cooled Countercurrent Flow reactor,” Chem. Eng. Sci., 56, 3719, 2001

- Ritchie, J.T., J.T. Richardson and D. Luss, “Ceramic Membrane Reactor for Synthesis Gas Production,” AIChE J., 47, 2001

- B. Q. Ming, J., M.D. Nersesyan, S. Lin, J.T. Richardson, D. Luss, A. A. Shiryaev,, “A new route to synthesize La 1-xSrxMnO3,” J Materials Sci., 35, 2000

- C. J. Khinast and D. Luss, “Efficient Bifurcation Analysis of Periodically-Forced Distributed parameter Systems,” Computers and Chem. Eng., 24, 139, 2000

- J.R. Claycomb, W. LeGrand, J.H. Miller, Jr M.D.Nersesyan, J.T. Ritchie,. and D. Luss, “Chemomagnetic Characterization of Chemical Reactions Using High TC-Squids,” Physica C, 341, 2641, 2000

- R. Garg, D. Luss and J.G. Khinast, “Dynamic and Steady-State features of a Cooled Countercurrent Flow reactor,” AIChE J., 46, 2029, 2000

- A. L. Wagner, A.J. Jacobson, J.T.Richardson, D. Luss, “Reaction Characteristics of La0..84Sr0.16 CrO3, Formation,” J Materials Sci., 34, 3055, 1999

- D. Luss and J. Khinast, “Efficient Bifurcation Analysis of Forced Periodic Processes,” in “Scientific Computing in Chemical Engineering II,” pp. 12-25, eds. Keil, Mackens, Vos, Werther, Springer Berlin, 1999

- J. Annamalai, M.A. Liauw and D. Luss, “Temperature patterns on a hollow cylindrical pellet,” Chaos, 9, 36, 1999

- J. Khinast and D. Luss, “Efficient Computation of Singularities of Chemical reactor Models,” in “Scientific Computing in Chemical Engineering II,” pp. 255-262, eds. Keil, Mackens, Vos, Werther, Springer Berlin, 1999

- J. Khinast, Y.O. Jeong and D. Luss, “Dependence of Cooled Reverse Flow reactor Dynamics on Reactor Model,” AIChE J., 45, 299, 1999

- Khinast, J., D. Luss, T.M. Leib, and M.P. Harold, “Impact of an Undesired Reaction on a Boiling–Slurry Reactor,” Chem. Eng. Sci., 54, 2295, 1999

- M. Shirayaev, M.D. Nersesyan, Q. Ming, D. Luss, “Thermodynamic Feasibility of SHS of SOFC Materials,” J. Mater. Synth. &. Proc., 7, 83, 1999

- M.D. Nersesyan, J.R. Claycomb, Q. Ming, J.H. Miller, Jr., J.T. Richardson and D. Luss, “Chemomagnetic fields produced by solid combustion reactions,” Appl. Phys. Lett., 75, 1170, 1999

- Q. Ming, M.D. Nersesyan, A. Wagner, J. Ritchie, J.T. Richardson, D. Luss, A.J. Jacobson and Y. L. Yang, “Combustion Synthesis and characterization of Sr and Ga doped LaFeO3,” Solid State Ionics, 122,113, 1999

- S.C. Lin, R. Wilkins, M. Nersesyan and D. Luss, “Combustion Synthesis of Cd-In-Ga-O Powder for Novel Thin film Growth substrate,” Ceramic Trans, 94, 23, 1999

- J. Khinast, A. Gurumoorthy and D. Luss, “Complex Dynamic Features of a Cooled Reverse-Flow Reactor,” AIChE J., 44, 1128, 1998

- J. Khinast, D. Luss, M. P. Harold, J. J. Ostermaier and R. McGill, “Continuously Stirred Decanting Reactor - Operability and Stability Considerations,” AIChE J., 44, 372, 1998

- J. Khinast, D. Luss, T. M. Leib and M. P. Harold, “Boiling-Slurry Reactor - Feasible Operation and Stability,” AIChE J., 44, 1868, 1998

- Q. Ming, J. Hung, Y.L. Yang, M.D. Nersesyan, A.J. Jacobson, J.T. Richardson, D. Luss, “Combustion Synthesis of La0.2Sr0.8Cr0.2Fe0.803-x,” Combust. Sci. and Tech., 138, 279, 1998

- Q. Ming, J., M.D. Nersesyan, S. Lin, J.T. Richardson, D. Luss, “Chemical Rate processes Involved in SHS of La0.9Sr0.1CrO3,” Int. J. Of SHS, 7, 1998

- S.C. Lin, R. Wilkins and D. Luss, “Self Propagating High-Temperature Synthesis of Cd-In-Ga-O Powder for GaN Thin Film Substrate,” Ceramic Trans, 86, 73, 1998

- D. Luss, “Temperature Fronts and Patterns In Catalytic-Systems,” Ind. & Eng. Chem. Res., 36, 2931, 1997

- J. Annamalia, C. Ballandis, M. Somani, M. A. Liauw and D. Luss, “Effects of Reactant Composition and Nonuniformities on Temperature Fronts,” J. Chem. Phys., 107, 1896, 1997

- J. Khinast and D. Luss, “Mapping Regions with Different Bifurcation Diagrams of a Reverse-Flow Reactor,” AIChE J., 43, 2034, 1997

- M. A. Liauw, M. Somani, J. Annamalai and D. Luss, “Oscillating Temperature Pulses During CO Oxidation on a Pd/Al2O3 Ring,” AIChE J., 43, 1519, 1997

- M. Somani, M. A. Liauw and D. Luss, “Evolution and Impact of Temperature Patterns During Hydrogen Oxidation on a Ni Ring,” Chem. Engg. Sci., 52, 2331, 1997

- M. Somani, S. Viswanath, J. Khinast and D. Luss, “Maximum Temperature In a Reverse - Flow Reactor with 2 Independent Reactions,” Chem. Engg. Sci., 52, 2483, 1997

- Q. Ming, M. Nersesyan, K. Ross, J. T. Richardson and D. Luss, “Reaction Steps and Microstruture Formation During SHS of La0.8Sr0.2CrO3,” Comb. Sci. & Tech., 128, 279, 1997

- T. Kohav, K. M. Forster, J. T. Richardson and D. Luss, “Effect of CO2 Concentration on YBa2 Cu3O6+X Formation,” AIChE J., 43, 1091, 1997

- D. Luss, “Chemical Reaction Engineering: Accomplishments and Challenges,” Proceeding APPCChE, 96, p.38, 1996

- F. C. Moates, M. Somani, J. Annamalai, J. T. Richardson, D. Luss and R. C. Willson, “Infrared Thermographic Screening of Combinatorial Libraries of Heterogeneous Catalysts,” Industrial & Engineering Chemistry Research, 35, 4801, 1996

- M. Somani, M.A. Liauw and D. Luss, “Hot Spot Formation on a Catalyst,” Chem. Eng. Sci., 51, 4259, 1996

- M.A. Liauw, J. Ning and D. Luss, “Pattern Formation on a Nonuniformly Active Ring,” J. Chem. Phys., 104, 5657, 1996

- M.P. Harold, J.J. Ostermayer, D.W. Drew, J.J. Lerou and D. Luss, “The Continuously Stirred Decanting Reactor: Steady State and Dynamic Features,” Chem. Eng. Sci., 51, 1777, 1996

- S.C. Lin, J.T. Richardson and D. Luss, “Continuous Synthesis of YBa2 Cu3O6+X by Thermal Explosion in a rotary Kiln,” Physica C, 260, 321, 1996

- T. Kohav, K.M. Forster, J.T. Richardson and D. Luss, “Effect of Ambient and Evolved CO2 on An Equilibrium Reaction in YBa2 Cu3O6+X Synthesis,” MRS Bull., 31, 1111, 1996

- Kohav, T., J.T. Richardson and D. Luss, “Axial Dispersion of Solids in a Continuous Rotary Kiln,” AIChE J., 41, 2465, 1995

- Middya, U. and D. Luss, “Impact of Global Interaction on Pattern Formation on a Disk,” J. Chem. Phys., 102, 5029, 1995

- Forster, K.M., Formica, J.P., Richardson, J.T. and D. Luss, “Solid-State Reaction Kinetics Determination via in situ Time-Resolved X-ray Diffraction,” J. Solid-State Chem., 108, 152, 1994

- Lin, S.-C., Richardson, J.T. and D. Luss, “YBa2Cu3O6+x Synthesis Using Vertical Selp-Propagating High-Temperature Synthesis” Physica C, 233, 281, 1994

- Middya, U. and D. Luss, “Impact of Global Interactions on Patterns in a Simple System,” J. Chem. Phys., 100, 6386, 1994

- Middya, U., Luss, D. and M. Sheintuch, “Spatiotemporal Motions Due to Global Interactions,” J. Chem. Phys., 100, 3568, 1994

- Middya, U., Luss, D. and M. Sheintuch, “Impact of Global Interaction and Symmetry on Pattern Selection and Bifurcation,” J. Chem. Phys., 101, 4688, 1994

- Milonopoulou, V., Forster, K.M., Formica, J.P., Kulik, J., Richardson, J.T. and D. Luss, “Influence of Oxygen Partial Pressure on the Kinetics of YBa2Cu3O7-x Formation,” J. Mater. Res., 9, 275, 1994

- Shelukar, S.D., Sundar, H.G.K., Semiat, R., Richardson, J.T. and D. Luss, “Continuous Rotary-Kiln Calcination of YBaCuO Precursor Powders,” Ind. Eng. Chem. Res., 33, 421, 1994

- Sims, W.B., Gaskey, S.W. and D. Luss, “Effect of Flow Regime and Liquid Velocity on Conversion in a Trickle-Bed Reactor,” Ind. Eng. Chem. Res., 33, 2530, 1994

- D. Luss, “Wrong-way Behavior of Packed-Bed Reactors,” Israel Chem. Eng., 22, 54, 1993

- Graham, M.D., Lane, S.L. and D. Luss, “Proper Orthogonal Decomposition Analysis of Spatiotemporal Temperature Patterns,” J. Phys. Chem., 97, 889, 1993

- Graham, M.D., Lane, S.L. and D. Luss, “Temperature-Pulse Dynamics on a Catalytic Ring,” J. Phys. Chem., 97, 7564, 1993

- Graham, M.D., Middya, U. and D. Luss, “Pulses and Global Bifurcations in a Nonlocal Reaction-Diffusion System,” Phys. Rev. E, 48, 2917, 1993

- Ilin, A. and D. Luss, “Wrong-Way Behavior of Packed-Bed Reactors: Influence of an Undesired Consecutive Reaction,” I&EC Res., 32, 247, 1993

- Lane, S.L. and D. Luss, “Rotating-Temperature Pulse during Hydrogen Oxidation on a Nickel Ring,” Phys. Rev. Lett., 70, 830, 1993

- Lane, S.L., Graham, M.D. and D. Luss, “Spatiotemporal Temperature Patterns during Hydrogen Oxidation on a Nickel Disk,” AIChE J., 39, 1497, 1993

- Lin, S.-C., Li, D.X., Semiat, R., Richardson, J.T. and D. Luss, “SHS of YBa2Cu3O6+x Using Large Copper Particles,” Physica C, 218, 130, 1993

- Middya, U., Graham, M.D. Luss, D. and M. Sheintuch, “Pattern-Selection in Controlled Reaction-Diffusion Systems,” J. Chem. Phys., 98, 2823, 1993

- Middya, U., Graham, M.D. Sheintuch, M. and D. Luss, “Patterns of Temperature Pulses on Electrically Heated Catalytic Ribbons,” Physica D, 63, 393, 1993

- Philippou, G., and D. Luss, “Temperature Patterns on a Catalytic Ribbon Heated by a Constant Voltage,” Chem. Eng. Sci., 48, 2313, 1993

- Philippou, G., Somani, M. and D. Luss, “Traveling Temperature Fronts on Catalytic Ribbons,” Chem. Eng. Sci., 48, 2325, 1993

- Sims,W.B., Schulz, F.G. and D. Luss, “Solid-Liquid Mass Transfer to Hollow Pellets in a Trickle Bed,” Ind. Eng. Chem. Res., 32, 1895, 1993