Faculty

Mike Harold is the Cullen Engineering Professor in the William A. Brookshire Department of Chemical and Biomolecular Engineering at the University of Houston (UH). With expertise in catalysis and reaction engineering, Harold has advised 39 doctoral students, authored 185 peer-reviewed papers and chapters, and presented 130 invited lectures. Through probing experiments and modeling spanning the molecular to reactor scales, Harold has advanced the understanding of fundamental aspects of reaction systems while providing useful guidance to practitioners. His research on multi-functional reactors and catalysts has led to reduced emissions and byproduct formation, and to more intensive and safer chemical reactors. Harold received his BS in Chemical Engineering from Penn State and PhD in Chemical Engineering from the University of Houston. In 1985 he joined the Chemical Engineering Dept. at University of Massachusetts where he became Associate Professor. In 1993 Harold joined DuPont Company, where he held technical and managerial positions. In 2000 Harold became the Dow Chair Professor and Department Chair at UH, a position he held in two non-consecutive terms for 16 years. Harold served as Editor-in-Chief of the AIChE Journal from 2012 through 2021, Chair of the AIChE Catalysis and Reaction Engineering Division in 1999 and 2022, and President of ISCRE Inc. in 2017-18. His honors include the R. H. Wilhelm Award from AIChE in 2023, the Award for Excellence in Applied Catalysis from the Southwest Catalysis Society in 2019, the Esther Farfel Award at UH in 2013, and AIChE Fellow in 2014.

Our research is in the area of catalysis and reaction engineering. We study problems which are of intrinsic academic interest while providing useful guidance and insight to practitioners. We carry out systematic, probing experiments combined with mathematical modeling spanning the molecular to the reactor scale. Current problems include:

- Catalytic oxidation and reforming of methane

- Catalysis with electrified substrates

- Forced dynamic operation for enhanced catalyst performance

- Plasma catalysis for conversion of alkanes to olefins

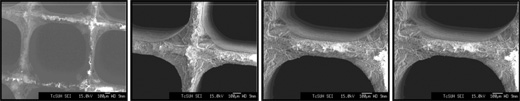

- Spatio-temporal studies of structured reactors

- Inorganic membrane reactors for hydrogen generation

- Graduate students: Chenhao Fang, Jonathan Ratcliff, Mohammad Moniruzzaman, Austin Morales (with P. Bollini), Kai Wu (with L. Grabow), Elmer Ledesma, Prajyot Srivistav

- Undergraduate students: Glynn Serida

R. H. Wilhelm Award, AIChE (2023)

Award for Excellence in Applied Catalysis, Southwest Catalysis Society (2019)

Fellow, American Institute of Chemical Engineers (2014)

Esther Farfel Award (top honor to university faculty member), University of Houston (2013)

Excellence for Research & Scholarship, Professor Level, University of Houston (2013)

Honorary Professor of Chemical Engineering, Tianjin University, Dept of Chemical Engin. (2013)

Pei Yang University Lectureship, Tianjin University (2013)

Fluor-Daniel Faculty Excellence Award, Cullen College of Engineering (2010)

Honda Initiation Grant Award, Honda Research Institute, “Enhancing Liquid Fuel Yield During Algae Pyrolysis in Structured Catalytic Reactors,” (5 awarded out of 261) (2010)

Outstanding Teaching Award, Cullen College of Engineering (2010)

Abraham Dukler Distinguished Faculty Award, Univ. of Houston, Engineering Alumni Assoc. (2009)

ACS Fuel Division Richard A. Glenn Award for Best Paper presented at ACS 2007 National Meeting Division of Fuel Chemistry (first out of 285 papers); Paper: “Hydrogen Generation and Purification in Pd Nanopore Hollow Fiber Membrane Reactor,” M. P. Harold and S. H. Israni (2008)

Senior Faculty Research Excellence Award, Cullen College of Engineering, U. of Houston (2008)

Best Applied Paper Award — Southwest Section of AIChE, 2007: Lattner, J.R., and M.P. Harold, “Autothermal Reforming of Methanol: Experiments and Modeling,” Catal. Today, 120, 78-89 (2007)

Selected Publications

- Mallapragada, D.S., Y. Dvorkin, M. Modestino, D. V. Esposito, W. Smith, B.-M. Hodge, M. P. Harold, V. M. Donnelly, A. Nuz, C. Bloomquist, K. Baker, L. C. Grabow, Y. Yan, N. Nidhi Rajput, R. Hartman, E. Biddinger, E. Aydil, A. Taylor, “Decarbonization of the Chemical Industry through Electrification: Barriers and Opportunities,” Joule, 7, 23-41 [https://doi.org/10.1016/j.joule.2022.12.008], 2023

- Ratcliff, J., K. Karinshak, P.W. Chen, and M.P. Harold, “Rich Methane Oxidation on Pt+Pd/Al2O3: Steady State Performance, Multiplicity Features, and Spatial Patterns”, Chem. Eng. Sci., 282, 119269 [https://doi.org/10.1016/j.ces.2023.119269], 2023

- Song, G., W. Zhou, C. Li, F. Hu, T. Wang, Z. Li, A. Tang, M.P. Harold, and S. Kawi, , “Semi-hollow LTA zeolite membrane for water permeation in CO2 hydrogenation to methanol,” J. Membrane Sci., 678, 121666 [https://doi.org/10.1016/j.memsci.2023.121666], 2023

- Chen, P.W., D. Maiti, L. Grabow, and M.P. Harold, “CH4 Steam Reforming on Pt+Pd/Al2O3 Monolith: Impact of Mn0.5Fe2.5O4 Spinel Addition”, Catalysis Science and Technology, 12, 2618-2633 [https://doi.org/10.1039/D2CY00270A], 2022

- Gupta A., M. Ambast and M.P. Harold, “NOx and Hydrocarbon Trapping and Conversion in a Sequential Three-Zone Monolith: Spatiotemporal Features,” ACS Eng. Au, 8, 515-534 [https://doi.org/10.1021/acsengineeringau.2c00023] , 2022

- Ambast, M., A. Gupta, B. M. Rahman, L. Grabow, and M.P. Harold,, “NOx Adsorption with CO and C2H4 on Pd/SSZ-13: Experiments and Modeling,” Appl. Catal. B. Environ., 286, 119871 [https://doi.org/10.1016/j.apcatb.2020.119871], 2021

- Ambast, M., A. S. A. Malamis, and M.P. Harold, “Coupled Uptake and Conversion of C12H26 and NO on Pd/SSZ-13: Experiments and Modeling,” Chem. Eng. J., 423, 129958 [https://doi.org/10.1016/j.cej.2021.129958], 2021

- Ghosh, R., M.P. Harold, and D. Wang , Selective Oxidation of NH3 in a Pt/Al2O3@Cu/ZSM-5 Core-Shell Catalyst: Modeling and Optimization,” Chem. Eng. J., 418, 129065 [https://doi.org/10.1016/j.cej.2021.129065], 2021

- Karinshak, K., P.W. Chen, R.F. Liu, and M. P. Harold, “Optimizing Feed Modulation for Coupled Methane and NOx Conversion over Pd-Pt/Mn0.5Fe2.5O4/Al2O3 Monolith Catalyst,” Appl. Catal. B. Environ., 304, 120607 [https://doi.org/10.1016/j.apcatb.2021.120607], 2021

- Zhou, Z., M.P. Harold and D. Luss, “Dynamic Oxygen Storage Capacity of Ceria-Zirconia and Mn0.5Fe2.5O4 Spinel: Experiments and Modeling,” Ind. Eng. Chem. Res., 60, 18, 6465–6482 [https://doi.org/10.1021/acs.iecr.0c05187], 2021

Selected Publications

- Bhatia, D., R.D. Clayton, M.P. Harold, and V. Balakotaiah, “A Global Kinetic Model for NOx Storage and Reduction on Pt/BaO/Al2O3 Monolithic Catalysts,” Catalysis Today, 147S, S250-S256, 2009

- Bhatia, D., V. Balakotaiah and M.P. Harold, “Bifurcation Analysis of CO and H2 Oxidation on Pt/Al2O3 Monolith Reactors.” Chem. Eng. Sci., 64, 1544-1558, 2009

- Bhatia, D., V. Balakotaiah, M.P. Harold, and R. McCabe, “Experimental and Kinetic Study of NO Oxidation on Model Pt Catalysts,” J. Catalysis, 266, 106-119, 2009

- Clayton, R.D., M.P. Harold, and V. Balakotaiah, “Performance Features of Pt/BaO Lean NOx Trap with Hydrogen as Reductant,” AIChE J., 55, 687-700, 2009

- Clayton, R.D.., M.P. Harold, V. Balakotaiah, and C.Z. Wan, “Effect of Pt Dispersion on NOx Storage and Reduction in Pt/BaO/Al2O3 Catalyst,” Appl. Catal. B. Environmental, 90, 662-676, 2009

- Israni, S.H., B. Nair and M. P. Harold, “Hydrogen Generation and Purification in a Composite Pd Hollow Fiber Membrane Reactor: Experiments and Modeling,” Catalysis Today, 130, 299-311, 2009

- Joshi, S., M.P. Harold, and V. Balakotaiah, “On the Use of External and Internal Mass Transfer Coefficients in the Transient Modeling of Catalytic Monolith Reactors,” Chemical Engineering Science, 64, 4976 - 4991, 2009

- Joshi, S., V. Balakotaiah, and M.P. Harold, “Low Dimensional Models for Real Time Simulation of Catalytic Monoliths,” AIChE J., 55, 1771-1783, 2009

- Kumar, A., V. Medhekar, M.P. Harold, and V. Balakotaiah, “NO Decomposition and Reduction on Pt/Al2O3 Powder and Monolith Catalysts Using the TAP Reactor,” Appl. Catal. B. Environmental, 90, 642-651, 2009

- Xu, J., M.P. Harold, and V. Balakotaiah, “Microkinetic Modeling of Steady-State NO/H2/O2 on Pt/BaO/Al2O3 Monolith Catalysts,” Appl. Catal. B. Environmental, 89, 73-86, 2009

- Clayton, R.D., M.P. Harold, and V. Balakotaiah, “Selective Catalytic Reduction of NO by H2 in O2 on Pt/BaO/Al2O3 Monolith NOx Storage Catalysts,” Appl. Catal. B. Environmental, 81, 161-181, 2008

- Clayton, R.D., M.P. Harold, and V. Balakotaiah, “NOx Storage and Reduction with H2 on Pt/BaO/Al2O3 Monolith: Spatio-Temporal Resolution of Product Distribution,” Appl. Catal. B. Environmental, 84, 616-630, 2008

- Muncrief, R.L., C.W. Rooks, M.P. Harold, and M. Cruz, “Combining Biodiesel and Exhaust Gas Recirculation for Reduction in NOx and Particulate Emissions,” Energy and Fuels, 22, 1285-1296, 2008

- Nair, B., and M.P. Harold, “Experiments and Modeling of Transport in Composite Pd and Pd/Ag Coated Alumina Hollow Fibers,” J. Membrane Sci., 311, 53-67, 2008

- Xu, J., R.D. Clayton, V. Balakotaiah, and M.P. Harold, “Experimental and Microkinetic Modeling of Steady-State NO Reduction by H2 on Pt/BaO/Al¬2O3 Monolith Catalysts,”Appl. Catal. B. Environmental, 77, 395-408, 2008

- Lattner, J.R., and M.P. Harold, “Autothermal Reforming of Methanol: Experiments and Modeling,” Catalysis Today, 120, 78-89, 2007

- Medhekar, V., V. Balakotaiah, and M.P. Harold, “TAP Study of NOx Storage and Reduction on Pt/Al2O3 and Pt/Ba/Al2O3,” Catalysis Today, 121, 226-236, 2007

- Nair, B., and M.P. Harold, “Pd Encapsulated and Nanopore Hollow Fiber Membranes: Synthesis and Permeation Studies,” J. Membrane Sci., 290, 182-195, 2007

- Nair, B., J. Choi, and M.P. Harold, “Electroless Plating and Permeation Features of Pd and Pd-Ag Hollow Fiber Composite Membranes,” J. Membrane Sci., 288, 67-84, 2007

- Sharma, M., R.D. Clayton, M.P. Harold, and V. Balakotaiah, “Multiplicity in Lean NOx Traps,” Chem. Engng. Sci., Chem. Engng. Science, 62, 5176-5181, 2007

- Kabin, K., P. Khanna, R. Muncrief, V. Medhekar, and M.P. Harold, “Monolith and TAP Reactor Studies of NOX Storage on Pt/BaO/Al2O3: Elucidating the Mechanistic Pathways and Roles of Pt,” Catalysis Today, 114, 72-85, 2006

- Nair, B., and M.P. Harold, “Hydrogen Generation in a Pd Membrane Fuel Processor: Productivity Effects During Methanol Steam Reforming,” Chem. Engng. Science, 61, 6616-6636, 2006

- Su, Y., K. Kabin, M.P. Harold, and M.D. Amiridis, “Reactor and In-situ FTIR studies of Pt Pt/BaO/Al2O3 and Pd/BaO/Al2O3 NOx Storage and Reduction (NSR) Catalysts,” Appl. Catal. B. Environmental, 71, 207-215, 2006

- Theis, J., H.W. Jen, R. McCabe, M. Sharma, V. Balakotaiah, and M.P. Harold, “Reductive Elimination as a Mechanism for Purging a Lean NOx Trap,” Society of Automotive Engineers Journal, 2006-01-1067, 2006

- Lattner, J.R., and M.P. Harold, “Comparison of Methanol Based Fuel Processors for PEM Fuel Cell Systems,” Appl. Catalysis B. Environmental, 56, 149-169, 2005

- Sharma, M., K. Kabin, M.P. Harold, and V. Balakotaiah, “Modeling of NOx Storage and Reduction for Diesel Exhaust Emission Control,” Society of Automotive Engineers Journal, OFL-125, 2005

- Sharma, M., M.P. Harold, and V. Balakotaiah, “Analysis of Storage and Reaction Phases for LNT for Diesel Engine Exhaust Treatment,” Society of Automotive Engineers Journal, OFFL-218, 2005

- Sharma, M., M.P. Harold, and V. Balakotaiah, “Analysis of Periodic Storage and Reduction in Catalytic Monoliths,” Ind. Engng. Chem. Res., 44, 6264-6277, 2005

- Bhattacharya, M. M.P. Harold, and V. Balakotaiah, “Shape Normalization for Catalytic Monoliths,” Chem. Engng. Sci., 59, 3737-3766, 2004

- Bhattacharya, M. M.P. Harold, and V. Balakotaiah, “Mass Transfer Coefficients in Washcoated Monoliths,” AIChE J., 50, 2939-2955, 2004

- Bhattacharya, M., M.P. Harold, and V. Balakotaiah, “Low Dimensional Models for Stirred Tank Reactors,” Chem. Engng. Sci., 59, 5587-5596, 2004

- Kabin, K., R. Muncrief, and M.P. Harold, “NOx Storage and Reduction in a Pt/BaO/Alumina Washcoated Monolith Catalyst,” Catalysis Today, 96, 79-89, 2004

- Kabin, K., R. Muncrief, M.P. Harold, and Y. Li, “Dynamics of Storage and Reaction in a Monolith Reactor: Lean NOx Reduction,” Chem. Engng. Sci., 59, 5319-5327, 2004

- Lattner, J.R., and M.P. Harold, “Comparison of Conventional and Membrane Reactor Fuel Processors for Hydrocarbon-Based PEM Fuel Cell Systems,” Inter. J. of Hydrogen Energy,29, 393-417, 2004

- Muncrief, R., K. Kabin, and M.P. Harold, “NOx Storage and Reduction With Propylene on Pt/BaO/Alumina,” AIChE J., 50, 2526-2540, 2004

- Muncrief, R., P. Khanna, K. Kabin, and M.P. Harold, “Mechanistic and Kinetic Studies of NOx Storage and Reduction on Pt/BaO/Al2O3,” Catal. Today, 98, 393-402, 2004

- Harold, M.P., B. Nair, and G. Kolios, “Hydrogen Generation in a Pd Membrane Fuel Processor: Assessment of Methanol-Based Reaction Systems,” Chemical Engineering Science, 58, 2551-2571, 2003